YG introduces you to a wet wipes making machine that produces 30-120 pieces of wet wipes. It has a very high degree of automation and high production output. A wet wipe production line automates the manufacturing, packaging, and sealing of wet wipes. The wet wipe production line consists of multiple workstations to realize the automatic production of wet wipes. According to different customer needs, the 30-120 pcs wet wipes making machine has 6 channels, 12 channels, and other models.

Raw materials: Spunlace non-woven, hot rolling non-woven fabrics, Air-laid paper, ect.

Finished products: alcohol wipes, daily wipes, baby wipes, shoe wipes, etc.

Production output: 6 lanes, 12 lanes, 16 lanes, 20 lanes, etc.

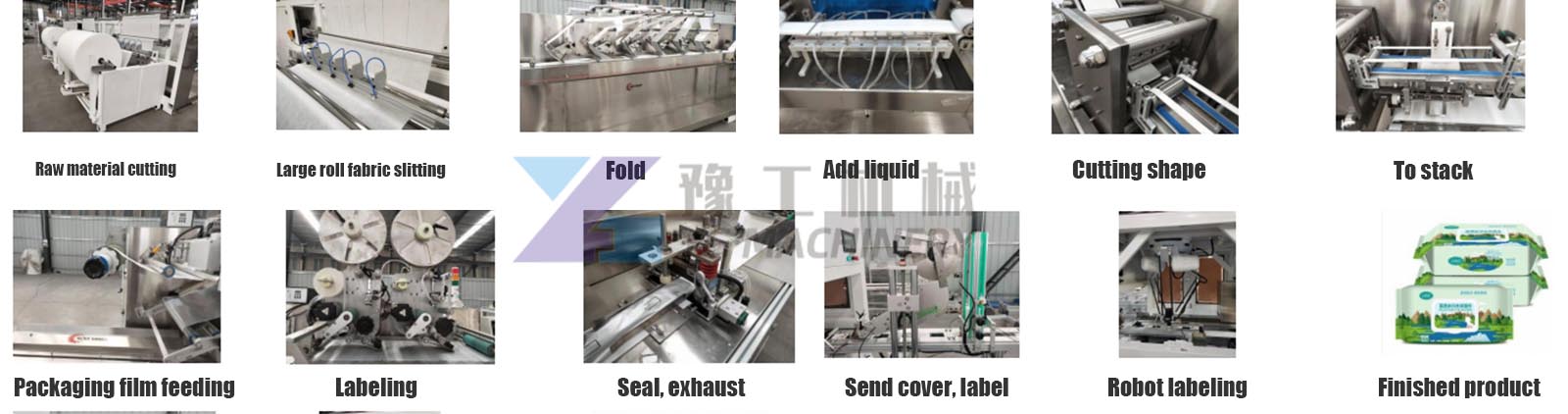

Operation steps: feeding, folding, adding liquid, cutting, printing and punching, labeling, packaging, finished product.

Folding method: Z, W, C, and other folding methods

| Suitable material | Spunlace,non-woven,hot rolling non-woven fabrics,Air-laid paper |

| Packing film | OPP/PE, PET/PE ,PET/AL/PE |

| GSM of raw material | 40-80g/m2 |

| capacity speed | 3500-4800psc/min (25-60bags) |

| Folding way | “Z” W”” C” types (pop-up and non-pop-up) |

| Size of product (unfolded) | (135-170)x(170-210);(MM)(LxW);(Modifiable) |

| Size of product (folded) | (135-170);x;(90-110)(MM)(LxW);(Modifiable) |

| Electrical source | AC380V;50/60Hz |

| Power | 15KW |

| Machine size | 12200mmX2450mmX2200mm (L×W×H) |

| Machine weight | 5000kg |

| Wetting system | one stainless steel water tank with an agitator |

| Control system: | Pre-programmed;full-auto PLC control system; Frequency;speed controlling |

| Punching;system | synchro;rotary;cutter |

| Counting;system | Auto-counting;(operation interface;setting) |

| Material;Loading;Device: | 2;holders;sliting into12;channels, automatic tension controller |

The production of wet wipes is mixing various raw materials paper and liquid, and then making wet wipes through cutting, packaging, and other processes. The complete production process of wet wipes is automatic feeding, cutting, liquid filling, cutting, stacking, packaging, and finished products.

First, the raw paper is folded into small pieces, which are then fed into a liquid spray machine. The liquid sprayer will evenly spray the pre-dispensed liquid on the paper to make the paper wet. Then, the cutting machine cuts the wet wipes into the required size and shape. Finally, use a wet wipe packaging machine to pack a certain amount of wet wipes into a bag. Automated production can also use a sealing machine to pack the produced pouched wipes in boxes.

Common wet wipe production equipment on the market can be divided into the following four types. They are a single sachet wet wipe machine, a 1-10 piece wet wipe machine, a 5-30 piece wet wipe machine, 30-120 piece wet wipe machine. Each type can also be divided into multiple models according to different needs. Among them, the 30-12 piece wet wipe machine is the more commonly used production equipment. In addition, YG also provides a wet wipe production line for cartridges. If you want to know more about wet wipe making machine, please contact us.

Want to know the detailed quotation of the equipment? Get solution configuration for free? Please leave a message~ We will come as fast as we can.

30min Quick ResponseOnline Message

If you are interested in our machine platforms or have any questions about how they work, then please get in touch using the following contact form.