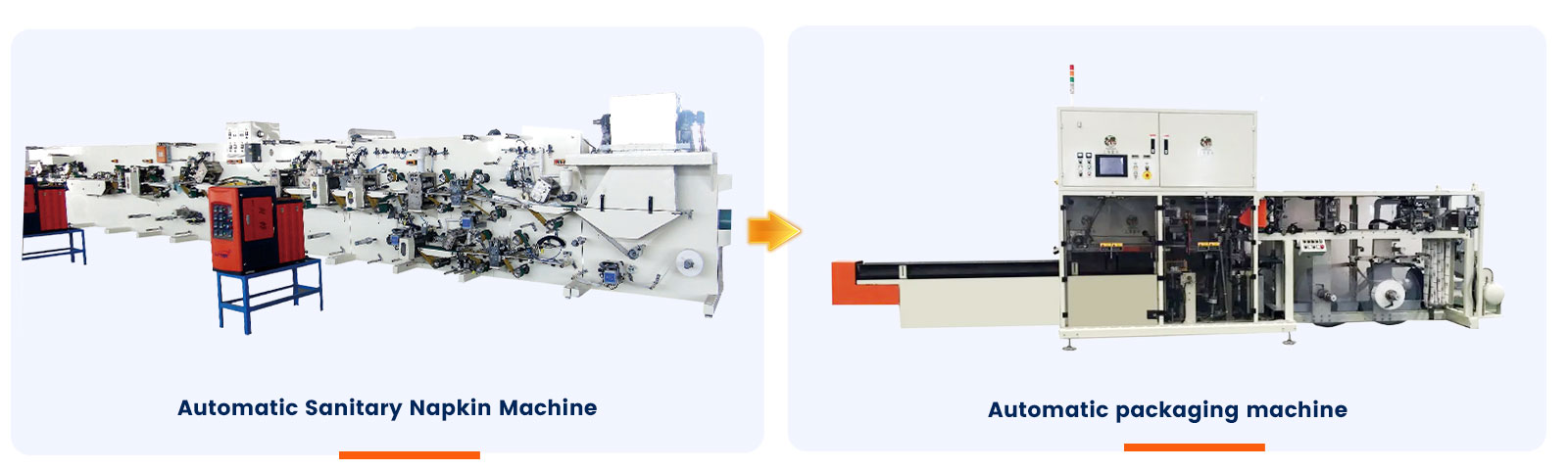

The sanitary napkin making machine is equipment for making feminine sanitary napkins. The main materials for making sanitary napkins are cotton-like pulp and polymer absorbents. An automatic sanitary pad machine is a tool to bond various raw materials for making sanitary napkins together. The sanitary napkin machine can also be used in conjunction with folding machines, packaging machines, sterilizers, and other equipment. YG tissue paper machine manufacture provides semi-automatic and fully automatic sanitary pad manufacturing machines. If you want to know more details about sanitary napkin machines, please contact us.

YG offers semi-automatic and fully automatic models of sanitary napkin machines. The following are the detailed introductions of the two sanitary napkin making machines.

Semi Automatic Machine

Semi Automatic Machine

Full Automatic Machine

Full Automatic Machine

Power Supply | power | yield | Product Dimensions | Machine dimensions | weight |

220V | 7.0KW | 80-120pcs/min | 250*160 | 4.0x1.1x1.6m | 900kg |

The semi-automatic sanitary pad making machine is suitable for small and medium-sized sanitary napkin plants, and its production capacity is 80~120pcs/min. Compared with manual production, the production capacity of the semi-automatic sanitary napkin machine is relatively high. Compared with fully automatic equipment, its price is cheaper. Therefore, this equipment is the best equipment for small and medium sanitary napkin manufacturing plants.

Performances | |

Volume (million pieces/ year) | 90-240 million pieces |

Designed Speed | 500pcs/min |

Stable Speed | 450pcs/min |

Passing Rate | ≥ 97% (Not include the glue applicator, Auto Splicing)

|

Technical Parameter: | |

Power Supply | 3 phase, 5 wires (380v, 50HZ) |

Power Installed | 250KW include Glue filter 250KW |

Power Used | 200KW |

Electric wire | 3×120mm2+1×50mm2+1×25mm2 |

Compressed Air Supply | 0.6~0.8Mpa |

Compressed Air Absorption | 4000 Nl/min |

Machine Size | 24.0m× 3m× 3m(L× W× H ) |

Working Size | 28m× 6 ´3.5m (L× W× H ) |

Machine Weight | about 40Tons (whole production line) |

Machine Color: | Confirm with Customer |

Machine Direction: | From Right to Left (can be designed as customer’s demand) |

Containers: | 4´ 40 HQ containers |

Product Size : | As customer’s requirement |

Product Type: | a.fluff core b. ultra thin

|

Product Structure: | |

Fluff core:top sheet、fluff core (with SAP)、back sheet、back release paper、wing release paper、pouch film、easy tape.

| Ultra thin:top sheet、air laid、SAP paper、back sheet、back release paper、wing release paper、pouch film、easy tape. |

Fully automatic sanitary pad making machine realizes automatic production from raw materials to finished products. The entire process is automated and only requires one or two people to operate the machine. This equipment has fast production speed and good quality finished products, it is an ideal equipment for large sanitary napkin manufacturing plants.

Because sanitary napkins are hierarchical, each layer needs to be prepared when making sanitary napkins. The structural layers of sanitary napkins and panty liners that are common on the market are generally 7-9 layers, which are also the raw materials that need to be used. When making sanitary napkins, it is necessary to use a sanitary napkin making machine to bond each layer with a water-based glue layer. Therefore, the raw materials needed to make sanitary napkins are placed on the frame of the machine, and the machine will automatically connect and glue the layers to make the final finished sanitary napkin.

RAW MATERIAL |

Style | CONSUMPTION OF EACH PIECE(GRAM) | |

ROLL PULP | 410MM*1200MM | 4.2 | |

PE FILM 1 | 1600MM*23G | 1.155 | |

PE FILM 2 | 160MM*25G | 0.8619 | |

TISSUE PAPER | 145MM*45G | 0.63 | |

NONWOVEN | 165MM*20G | 0.963 | |

SILICON PAPER

| 45MM*42G | 0.2321 | |

60MM*42G | 0.345 | ||

HOT MELT GLUE | STRUCTURE GLUE | 3520 | 0.5 |

POSITION GLUE | 3580 | 0.35 | |

SAP | SA-60N | 0.4 | |

FAST&EASY STICKER | 800M*28MM | 10mm | |

The raw materials needed to make sanitary napkins mainly include roll pulp, cast film, packaging film, toilet paper, non-woven fabric, release paper, hot melt adhesive, SAP, FAST&EASY STICKER, and other raw materials. The following are the consumables needed to make a single-piece sanitary napkin. If you want to know more, please leave us a message.

With the continuous improvement of the education level of women in the world, their status and consumption ability are gradually improved. Women's awareness of personal health continues to increase, and the frequency and consumption of sanitary napkins continue to increase. As a disposable consumer product, sanitary napkins have a considerable annual consumption. According to the survey, the market size of China's feminine hygiene products in 2021 will be 98.71 billion yuan. Feminine hygiene products accounted for 57% of the market. Therefore, the sanitary napkin machine manufacturing business is definitely profitable.

If you want to choose the right equipment for your sanitary napkin manufacturing business, take a look at the selection below.

Please choose the sanitary pad making machine and supporting equipment according to the production scale of your factory. Any questions, please contact us.

Want to know the detailed quotation of the equipment? Get solution configuration for free? Please leave a message~ We will come as fast as we can.

30min Quick ResponseOnline Message

If you are interested in our machine platforms or have any questions about how they work, then please get in touch using the following contact form.