The toilet paper packaging machine is the last step in toilet paper production and is used for packaging toilet rolls. It is suitable for the packaging of cored toilet rolls and coreless toilet rolls. YG offers a variety of toilet paper packing machines for the production of single rolls, medium packs, and large packs of toilet paper. The sealing effect of the finished product packaged by the automatic toilet paper wrapping machine is beautiful, and the packing speed is fast.

Toilet paper packaging generally has single packs, medium packs, and large packs. The medium package is usually a mention, which contains ten volumes, twelve volumes, fifteen volumes, etc. Large packs generally contain 24 rolls, 32 rolls, 36 rolls, etc.

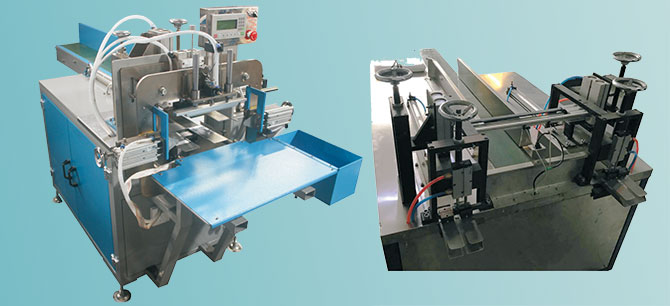

According to the above toilet paper packaging plan, YG developed and produced the following three toilet paper packing machines with different degrees of automation. They are manual sealing machines, semi-automatic packaging machines, and automatic toilet paper wrapping machines.

| Packing speed | about 20 packs/minute |

| Packing specifications | length: 90-210mm; width: 90-100mm; height: 40-100mm |

| Total power | 3.41KW |

| Motor power | 0.61KW |

| Air source pressure | 0.5MPa |

| Machine net weight | 400kg |

| Dimensions | 4000×2500×1200 (mm) (height adjustable) |

| Power type | 380V |

| Material of heat sealing bag | CPP |

| rated speed | 110bages/min |

| design speed | 120bages/min |

| Packing Specifications | Length 100-140mm, diameter φ60-φ140mm |

| Total power | 4.24kW |

| Machine noise | ≤70dB |

| Machine net weight | 1500kg |

| Overall size | 6730×1310×1480 (mm) |

| Voltage | 380v、50Hz |

| Packing material | BOPP、PE/OPP 、CPP、PP, etc. |

The packaging materials currently on the market for packaging toilet rolls are all plastic packaging. Usually PET or PE film. This is mainly due to two considerations, one is cost, and the other is protection. Toilet roll is a daily fast-moving consumer product, and the cost of using plastic packaging is relatively low. The plastic bag can protect the toilet paper from the air. Toilet paper has a strong adsorption capacity and can avoid contact with bacteria or dust in the air.

For the above toilet paper packaging machines, how should we choose the right one? If you run a small toilet roll manufacturing plant, then I recommend you start with a manual sealer. A slightly larger scale can choose semi-automatic equipment. If your factory is relatively large and has a sufficient budget, then you can choose fully automatic toilet roll packaging equipment.

Since YG provides the above types of toilet paper packaging machines, the price of the machines is not fixed. And each type of toilet paper packing machine also has many different models. If you want to know the price of the toilet paper packaging machine, please leave us a message.

Want to know the detailed quotation of the equipment? Get solution configuration for free? Please leave a message~ We will come as fast as we can.

30min Quick ResponseOnline Message

If you are interested in our machine platforms or have any questions about how they work, then please get in touch using the following contact form.